RESEARCH PROGRAM

Title: Optimization of the cooling channel outlet conditions of internally cooled drills

Name: Daniel Müller

E-Mail: daniel.mueller@mv.uni-kl.de

Phone: 0631 – 205 - 3385

Project description:

Starting situation

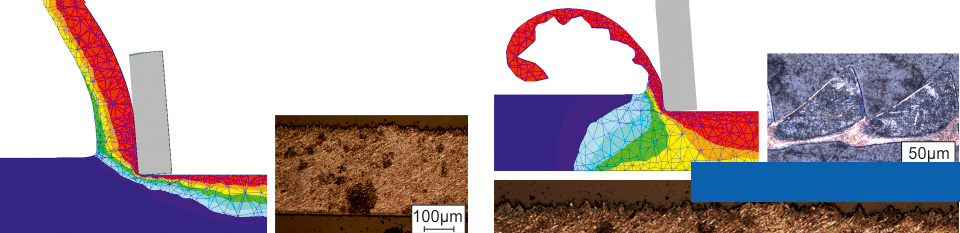

Drilling is one of the most common cutting processes. However, due to the process conditions, the process is difficult to be controlled. Drilling tools such as cemented carbide twist drills with split point geometry are exposed to high mechanical and thermal loads. The cutting zone is located inside the workpiece, making it challenging to provide sufficient metal working fluid to the cutting edges and hence to cool down the workpiece and the tool. To handle this issue, the fluid is delivered through channels inside the tools to the flank face. The design and position of the cooling channel outlets at the flank face of the tool highly influences the cooling efficiency and tool wear.

Approach

1st Step: Design of drills with different channel positions, numbers, sizes and shapes

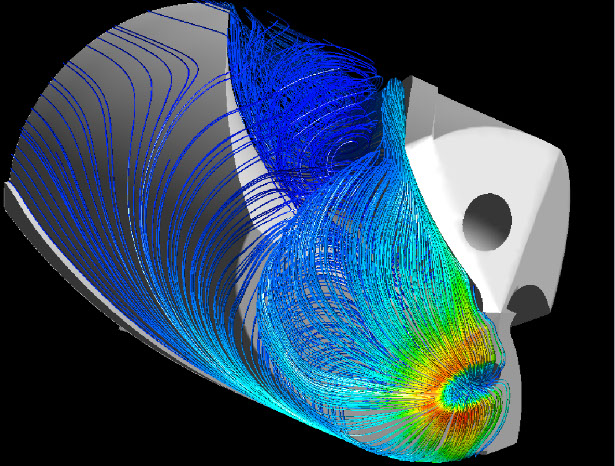

2nd Step: Numerical simulation of the drills at different flow rates

3rd Step: Experimental investigations regarding the cooling channel outlet conditions’

influence on the thermal load of the drills and the quality of the boreholes

4th Step: Experimental investigations concerning the influence of the cooling channel outlet

conditions on the tool lifetime

Expected Results

The aim of the project is to develop rules for the design of internally cooled drills’ cooling channel outlet conditions for a more efficient cooling lubricant. It is expected to improve tool life and the removal rates when drilling with low metal working fluid.

Figure 1: simulated streamlines of a drill