RESEARCH PROGRAM

Title: Planning and controlling of multiple, parallel engineering changes in manufacturing systems

Name: Dr. Daniel Cichos

(former student)

Project description:

Starting situation

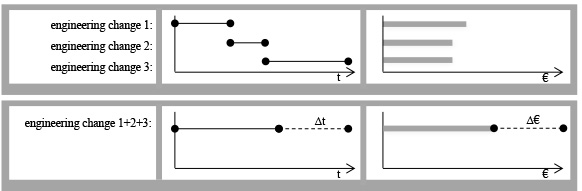

Due to changing customer demands and new technologies, manufacturing companies have to adapt their production program. A multitude of engineering changes in manufacturing systems must be performed to adapt existing factories to these developments. The coordination of several engineering changes in manufacturing systems is a key factor for the efficiency of the planning and execution. With an optimal planning duplication of work is avoided and synergy effects are achieved in parallel projects.

Approach

The starting point is the generation of representative production scenarios. Based on defined engineering changes, interactions and dependencies between parallel engineering changes are identified. Prioritization, time scheduling and control of multiple, parallel engineering changes need to be considered. First, Prioritization classifies the engineering changes with regard to their relevance and urgency. Then, the changes can be combined strategically according to the effect on the manufacturing systems. For time scheduling the available resources are forecasted first. Following the resource load is identified and potential bottlenecks are captured. For the control of engineering changes, rules are defined by using event-driven process chains (EPC). EPC initiate an adaption in the planning if an intervention is required due to the occurrence of unplanned events. The developed method is then implemented in a software demonstrator. This serves to validate the method based on a typical industrial use case.

Expected Results

The advantages of a joint planning and implementation of several engineering changes are, on the one hand, the time advantage due to parallelization. On the other hand, cost advantages arise because work steps are coordinated and double work is avoided. The more complex planning and controlling of multiple engineering changes can be handled by this method for the planning and controlling engineering changes.

Saving time and money due to parallelization of engineering changes in manufacturing systems