RESEARCH PROGRAM

Title: Visualization and interaction techniques scaling on process and environment level

Name: Dr. Franca Alexandra Rupprecht

(former student)

Project description:

Starting situation

In virtual manufacturing systems, manifold scaled transactions from the factory level (higher-level) via machine level to process level (and vice versa) have to be taken into account. Factory-level transactions describe the general material flow within the whole manufacturing process. Machine level transactions specify different manufacturing processes on the workbench level. Finally, process-level transactions describe detailed characteristics in single manufacturing processes (e.g. cutting). In order to achieve a sustainable production process in general, on each level, the user has to be able to control and adapt these transactions. In a virtual environment, one should not only be able to change the parameters of single process chain components, but also to re-parameterize the whole simulation (e.g. by changing the positions of machines in order to optimize the whole process).

Parallel to the different levels of transactions in manufacturing processes, the used visualization and interaction methods should automatically adapt to the respective transaction level, i.e., they should scale with that level. On the one hand, the simulation and visualization of a complete manufacturing process at factory level should be placed into a large virtual environment (e.g. a CAVE). The common work with those VR technologies is carried out with the use of one presenter, who is interacting with the model and several spectators. However, collaboration between different users with those technologies is sorely affected by the interactions of the users therefore it is difficult to perform collaborative work exclusively with a CAVE system. Here, powerful but intuitive visualization and interaction possibilities are needed, for example an eyes-free control of the complete environment with a mobile device. Next to the navigation and manipulation of the 3D model, mobile devices could be used to provide additional in-/output to the users and appropriate further interaction and visualization techniques to enable collaborative work in virtual manufacturing systems.

Approach

In this research project, we propose to develop and evaluate human-centered visualization and interaction techniques that scale both with the level of the transaction to be considered and with the used devices. In order to achieve these research objectives, the first step will be to develop visualization techniques that appropriately transform the simulation models into a three-dimensional virtual environment and that additionally are able to handle different transaction levels. Besides powerful visualization techniques, appropriate interaction methods are an important issue in large display environments. Intuitive interaction mechanisms for optimal support of the tasks and for providing collaborative work in the virtual environment need to be researched and evaluated (e.g. the integration of mobile devices for interacting with the 3D scenarios).

Expected Results

Human-centered virtual production environment achieved by the development of a highly scalable visualization/interaction framework, focusing on the cross product of visualization, interaction and collaboration.

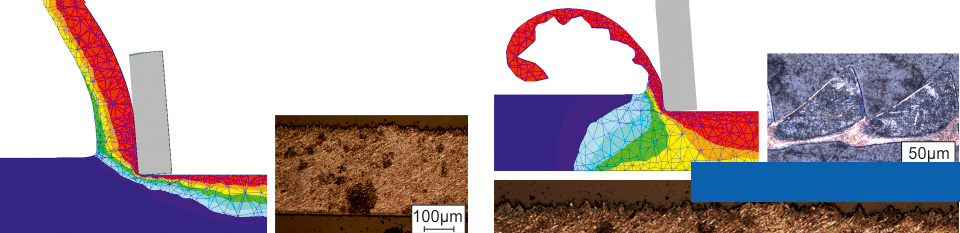

Figure: Interacting with a large stereoscopic environment with a mobile device