RESEARCH PROGRAM

Title: Virtual test field for sustainability assessment of cybertronic production systems

Name: Dr. Rebecca Ilsen

(former student)

Project description:

Starting situation

Companies of the manufacturing industry need to adapt their product portfolio and their production system to cope with shorter product life cycles and higher complexity of individualized products. In the same time they need to respond to requirements from legislature, market and society regarding resource efficiency and social responsibility.

In this context companies create cybertronic production systems (CTPS) and try to implement useful links between virtual and real processes in manufacturing on all levels of detail. The transition to cybertronic production systems is hindered by uncertainty about how it works, if it works and what impacts are to be expected concerning working conditions, production efficiency and robustness of processes.

Approach

Therefore a virtual test field to simulate a cybertronic production system is implemented that allows to analyze system behavior as well as economic and ecological impacts.

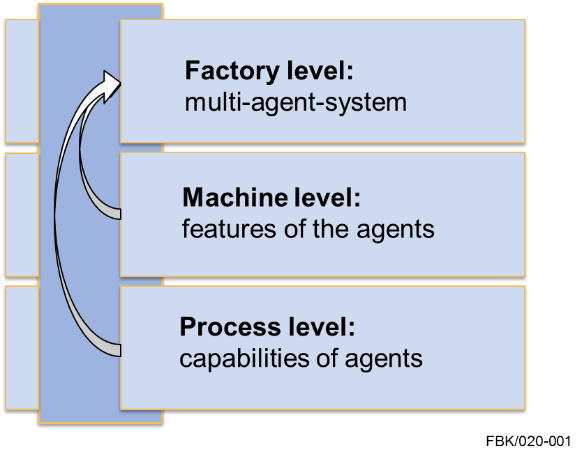

The simulation approach is based on a multi-agent-system of a production system. On factory level all elements of a production system, whose output can be changed by a control system, will be modelled as agents. This comprises facilities (e.g. machine tools), transport and handling devices as well as supply facilities (e.g. energy and building technology).

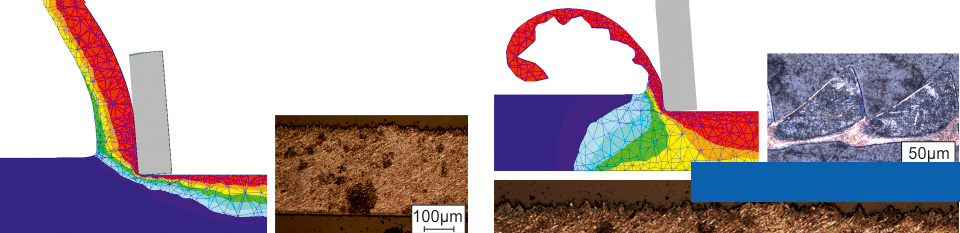

To depict their behavior, detailed data and models of the machine and process level are required. These data and models describe abilities (e.g. excellence of the machining process, set-up times, consumption and so on) of the machines as well as the influencing factors for these abilities. Data for the abilities are gathered in cooperation with other research projects from the IRTG 2057.

Verification of the simulation model as well as analysis of simulation results is done by methods of high performance computing in cooperation within the IRTG.

Expected Results

The project provides a virtual test field to simulate technical and organizational changes in a production system on process, machine and factory level and enables to analyze and quantify their impacts on implemented sustainability indicators.

Figure 1: Scale bridging model structure