RESEARCH PROGRAM

Title: Sustainable Grinding Machine Tool Design

Name: Ian Garretson

E-Mail:

Phone:

Project description:

Starting situation

Energy consumption in the US and Europe is correlated to economic growth and thus manufacturing growth. Design of manufacturing machine tools for improved sustainability can influence future sustainability trends and potentially decouple energy consumption from economic growth. Machine tool design has historically focused on product quality, throughput, and return on investment, although not always simultaneously. A shift is needed in design techniques that concentrate on sustainability metrics.

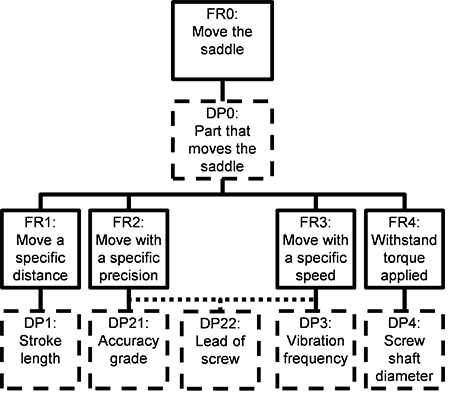

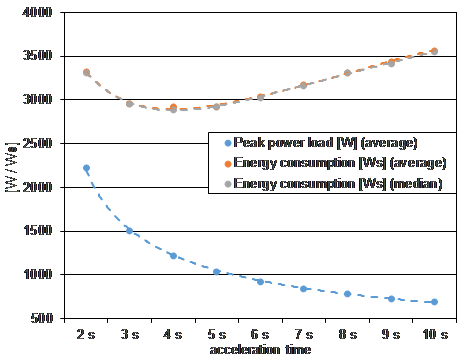

Initial studies have been performed on analysis of grinding machine components. Studies include an analysis of torque requirements and energy use of lead screw, and a study on energy consumption during the acceleration of a pedestal grinder. Additional subsystems of a grinding machine to analyze include the coolant system, oiling system, measurement systems, moving masses, and control system.

Approach

1. Identify key machine tool components and subsystems

2. Develop first-principles-based mathematical description for individual subsystems

3. Quantify sustainability metrics of different designs

4. Analyze tradeoffs between designs to optimize machine components and subsystems

Expected Results

Machine tool use is ubiquitous across manufacturing industries; every industry uses some kind of machinery. Designing machine tools for sustainability performance will have additive effects across industries. Expected results include reduced energy consumption and material use in product manufacturing. An expected output is design methods for machine tool design engineers.

Figure 1: Functional Decomposition of Lead Screw Design

Figure 3: Peak power and Energy Consumption for a Grinding Machine