RESEARCH PROGRAM

Title: Simulation of Energy Demand of Additive Manufacturing

Name: Dr.-Ing. Li Yi

E-Mail: li.yi@mv.uni-kl.de

Phone: 0631 – 205 - 3304

Project description:

Starting Situation

Additive Manufacturing (AM), also called 3D Printing, defines a process in which a part is manufactured by joining material layers, representing an opposite to conventional subtractive and formative manufacturing methods. In the context of sustainable manufacturing, AM enables a reduction of energy demand by the means of reduction of system and process complexity. For example, AM does not require auxiliary materials or equipments (e.g. casting form or cooling lubricant), which are necessary in conventional manufacturing processes, and is supposed to save energy.

In current research status, there are still two remaining research questions. The first one is how to predict the energy demand of AM already in an early phase with high accuracy but without direct measurement, avoiding the high cost of experimental investigation. The second question is what the relationship between the manufacturing quality (e.g. surface quality) and energy demand of AM technology is. Therefore, the ongoing project aims at these two research questions, and proposes a simulation-based approach to calculate the energy demand of AM technology with regard to the manufacturing quality.

Approach

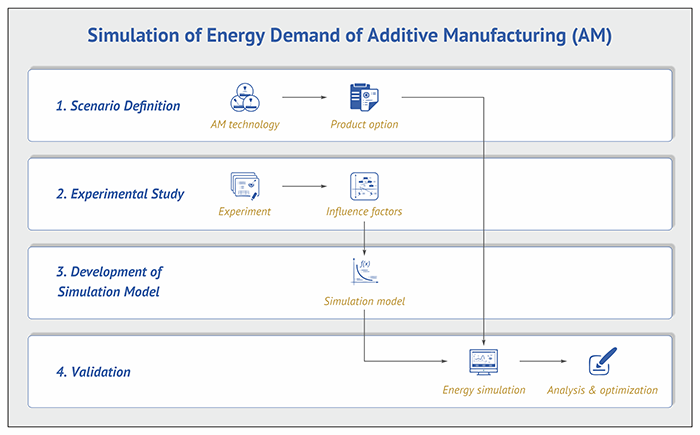

The approach of this project is visualized in Fig.1 and includes the following four steps. In the first step, AM technologies as well as available machines are analyzed, in order to select one AM process as reference technology. Afterwards, different product options should be identified as manufacturing scenario. The second step is to carry out an experimental study, investigating the influence factors and interdependencies between manufacturing quality and energy demand of AM. In the third step, a simulation model to predict energy demand of AM will be developed according to the results of the experimental study. Finally, the simulation model will be tested by the defined manufacturing scenario and optimized.

Expected Results

The first expectation is to identify the interdependencies between manufacturing quality and energy demand of AM technology. The second expectation is to develop and to validate the simulation model of energy demand of AM, allowing the prediction of energy demand of AM in an early phase with high prediction accuracy and good feasibility. The results obtained from this project should be helpful for other researchers or designers to analyze and optimize the energy performance of their own cases related to AM.

Fig.1: Overview of the approach