RESEARCH PROGRAM

Title: Simulation of machining with cutting liquids based on atomistic force fields

Name: Martin Lautenschläger

(former student)

Project description:

Starting situation

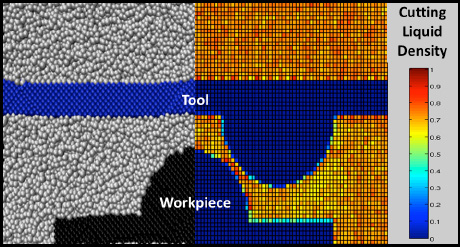

Lubrication, heat transfer, and dynamic wetting will be considered as the elementary processes which occur simultaneously during machining with cutting liquids. Experimentally, the processes at the cutting edge can hardly be investigated in a reliable way, since they occur on the nanometer length scale under large gradients in the fluid as well as large heat and mass fluxes, so that the thermodynamic conditions become space and time dependent. In a molecular dynamics (MD) simulation, however, the processes can be studied in a well-defined way by employing a suitable non-equilibrium MD (NEMD) approach.

Approach

An understanding of the entire, highly complex process has to be preceded by the systematic investigation of the individual phenomena, particularly in the linear response regime, where the corresponding transport coefficients remain approximately constant. Moreover, processes which drive a system very far from thermal and mechanical equilibrium are not sufficiently characterized by linear (i.e. constant) transport coefficients. Since machining can expose cutting liquids to extreme stresses and temperature gradients, it is necessary to obtain a description of the fluid under shear linear regime as well. Therefore, it is crucial to employ fluid models that reflect the basic properties of typical cutting liquids without reproducing all properties of a multi-component mixture in detail. In a later stage of the project, we also aim at studying the mechano-chemical coupling, i.e. the chemical decomposition of cutting fluids under the extreme thermal and mechanical stress, using reactive force fields.

Expected Results

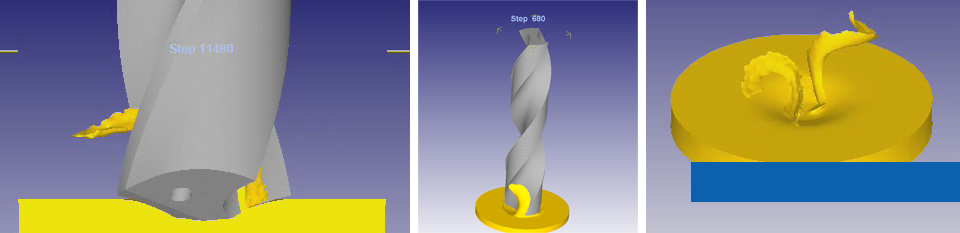

This project aims at gaining a detailed insight in the elementary processes of machining with cutting liquids on the atomistic level. MD - as a fully predictive method - will be used to investigate the interactions in a solid-fluid-solid system, such as the important influence of the roughness of the machining tool and the workpiece as well as material properties of the cutting liquid. In that context, the project focusses on developing models for representative components of cutting liquids like paraffinic, aromatic, and naphthenic mineral oils. By that, atomistic properties will be systematically varied, and scale-up studies will be carried out. A transfer of MD results to higher-level approaches such as the particle finite element method (PFEM) will be achieved. Finally these results will help to design tools and cutting liquids with the aim to improve energy and resource efficiency during machining.

Figure: From Molecular Dynamics (left) to Material Properties (right)

Investigation of the effects of molecular interaction during machining on physical state variables

and material properties of tool, workpiece and the cutting liquid in particular