RESEARCH PROGRAM

Title: Thermal field variations due to perturbations of laser power input in an SLS process

Name: Nicolas Castrillon

E-mail: Nicolas.castrillon@berkeley.edu

Phone: +1 (954) 873-4755

Motivation

Selective laser sintering (SLS) is an advanced additive manufacturing (AM) process that is prevalent in industries that are interested in prototyping and massively manufacture metal parts, including rocket fuel injectors and entire homes. However, fine tuning an SLS process on the factory floor is typically performed in a trial-and-error fashion, greatly reducing the productivity of the design process. It follows then that quantifying the sensitivities of the output printed component with respect to the input design parameters is attractive to industry.

Method

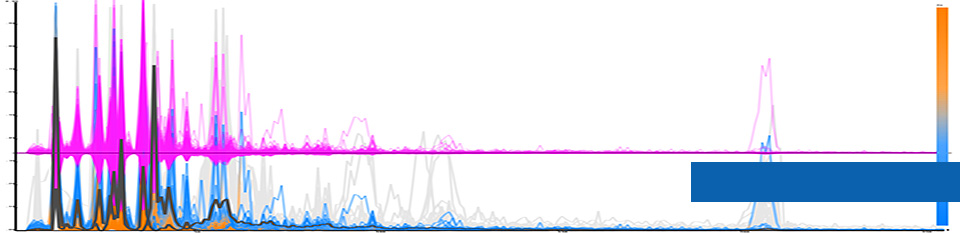

Quantifying sensitivities of quantities of interest (QoI), such as max stress or structural compliance, has been demonstrated by a myriad of previous topology optimization work. My aim is to leverage these optimization formulations by way of an adjoint problem to and apply them to a QoI that is pertinent to the SLS process; in my case, the thermal field. Once the variations of the thermal field of the powder bed with respect to perturbations of the input laser energy are understood, geometric heuristics can be used to measure the extent of the melt pool in 3D. These geometric heuristics can be used to ultimately qualify a print as geing “good” or “failed.”

Expected Results

The quantification of sensitivities of the domain (irradiated powder bed) will provide an understanding on optimal input design parameters (thermal input) to yield components that approach the original design intent. This data can be further used to generate “keep out” design parameter ranges that correlate with high sensitivities of the resulting thermal field, making the tuning of the SLS process on the factory floor extremely difficult and yielding a wide variety of poorly-performing components.