RESEARCH PROGRAM

Title: Visual Analytics for Stochastic Parameter Space Exploration in Multi-field Simulations

Name: Patrick Rüdiger-Flore

E-Mail: ruediger@rhrk.uni-kl.de

Phone: 0631 – 205 - 3501

Project description:

With the increasing digitalization of factory and manufacturing planning and engineering the data produced no longer can be summarized in a single snapshot. Having already pursued a lot of effort in analyzing 1d, 2d and lately 3d field data, the challenge now is to deal with multiple outcomes at once and therefore not only incorporating unsteady (time-dependent) data but also correlating the results from multiple sources like simulations, measurements etc. This way the task of bridging the layers from process to manufacturing to factory level is getting to a new level of complexity.

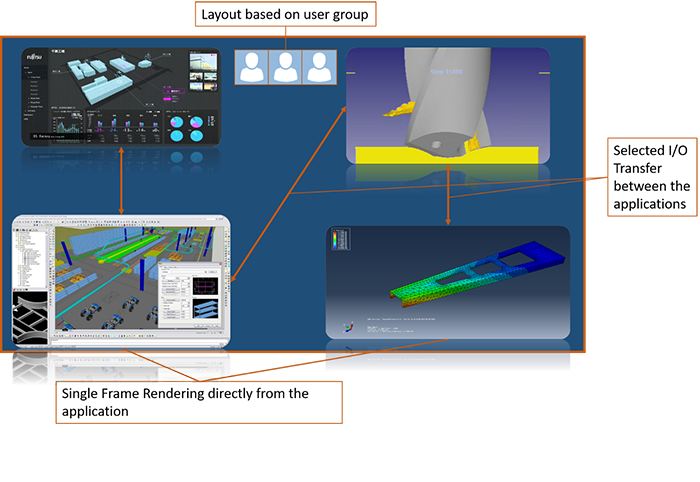

The aim of this project is to provide insights in the correlation of all levels by investigating the needs in analysis and communication of every discipline. Doing so, we set up on state-of-the-art technologies and built a framework that allows the user to seamless integrate his results in one environment.

Approach

There are multiple challenges that occur in this special setup and that we want to address. First the heterogeneous data. Heterogeneous in this context is on the one hand referred to the source of creation, e.g. simulation, measurement, etc. and on the other hand to the structure of the data itself, e.g. dimension, resolution, time-variance, statistics, …. Additionally, different disciplines are using different data formats which are not always seamless transferable. Second the complexity and size of the data. Especially simulations create an increasing amount of data, now correlating multiple of these results multiply the complexity for analysis and demand for new solutions. The aim therefor is to enable a distributed and in-situ analysis of the data as a normal desktop won’t be capable of processing all the data anymore. With that goal in mind communication of software and systems is an issue as well.

Expected Results

The results of this project will enable the scientists to evaluate the impact of their work on the whole process and enabling new ways of collaboration and joining efforts to further optimize their technologies.

Fig.1 Concept of a multi-level and adaptable virtual manufacturing dashboard, serving as an experimental setup.