RESEARCH PROGRAM

Title: Physical Modeling of grinding forces

Name: MSc. Praveen Sridhar

E-Mail: praveen.sridhar@mv.uni-kl.de

Phone: +49 (0) 631/205-5101

Project description:

Starting Situation

Grinding is a highly complex and dynamical process which faces many challenges in modelling the geometrically undefined and stochastically distributed engagements of grits and work piece. For detailed process prediction, as quality of the ground surface, energy consumption, heat generation or dynamical excitation, a precise description of the grinding forces is necessary. The occurring grinding forces are thereby strongly related to the material properties of the machined part, the process parameters, and the local indentation condition of the grits, such as rubbing, ploughing or cutting. However, due to the complexity of the grinding process, force predictions mostly include empirical relations which are limited to specific wheel/work piece combinations and are tedious to parameterize. Hence, more general concepts of grinding force calculations are preferable which are not limited to specific application cases. A physical force model will significantly reduce the experimental parameterization effort, and will fulfill the demand on reliable models for virtual process planning.

Approach

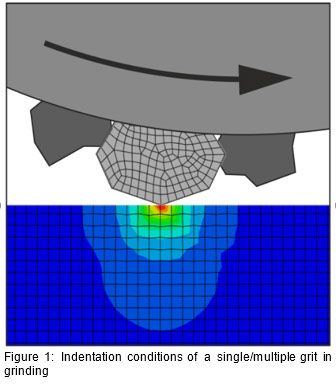

Development of the physical force model for simulation of single grit indentation and grinding, taking in only physical parameters such as kinematic parameters, material (workpiece and grit) parameters and grit specifications as inputs.

The physical force model is then coupled with a damage-failure model and an appropriate contact model to simulate the material damage mechanisms for ductile as well as brittle materials.

The physical model will be developed using the finite element method (FEM). Two types of FE models are planned to be implemented: 2D models to simulate the cutting operation and 3D models to simulate the rubbing and ploughing operations.

Expected Results

Validation of the physical force model with process specific experiments, designed and conducted in single/multiple grit indentation test setups as well as complete grinding wheel test setup.

The validated model is used to study the effects of grinding forces, variation in chip formation and material removal mechanisms in grinding by varying the input parameter set.