RESEARCH PROGRAM

Description of the core research idea and the IRTG’s resulting main focus

The central research idea formulated at the beginning of IRTG 2057 was to apply physical modeling and simulation to plan, analyze, and optimize virtual manufacturing on all levels; that is Process, Machine and Factory. An important part of the overall research idea was to use novel interactive visualization and analysis methods from computer science to create new answers to research questions in manufacturing engineering. The participation of scientists from physics contributed to advancing models and simulations by including physical properties of the factory objects.

The International Research Training Group IRTG 2057 had three main objectives: educating and training the next generation of engineers and computer scientists, advancing technology and methods used in manufacturing systems and processes, and establishing a seamless cooperative environment between RPTU in Kaiserslautern, UC Davis, and UC Berkeley. The educational work has proven to be extraordinarily successful with graduates starting promising careers on both the academic and industrial job markets. The research objective of this IRTG, advancing technology and methods used in manufacturing systems and processes by applying scientific fundamentals and novel computational methods in conjunction with physics-based models, has proven to be of exceptional high scientific and industrial value over the past nine years. The digital revolution in manufacturing has taken up speed and the central scientific goal of this IRTG, creating physical models for manufacturing systems and processes, is at the core of the fourth industrial revolution. In the course of the nine years, manufacturing technologies were expanded from material removal processes to additive manufacturing technologies, recognizing the developments in this field. Being a rather new manufacturing technology, the IRTG helped to establish novel and first-time physical models for additive manufacturing. The third objective, establishing a seamless collaborative environment between the three partner universities, has been implemented with exceptional success as well. 130 exchange visits of PhD students and postdoctoral researchers, 99 visits by professors, online and social media activities of all IRTG members, 30 cases of professors serving on thesis committees at the partner universities, 68 joint publications between RPTU Kaiserslautern-Landau, UC Davis and UC Berkeley, the organization of three international conferences, and two jointly published journal issues: the ambitious goal of creating an integrated global academy was achieved.

Description of the starting situation and central research idea of the IRTG

The use of computer-based virtual models and simulations in the planning, analysis, and optimization of manufacturing systems has been common engineering practice since more than two decades. However, these models were still often purely geometrical such as in a computer-based material flow simulation or in a virtual reality model used to plan a factory. Simu¬lations of single manufacturing processes already included some real physical phenomena, i.e. via finite element (FE) or molec¬ular dynamics (MD) methods, but without connection to other simulations or to an overall framework.

The central research idea formulated at the beginning of IRTG 2057 was to apply physical modeling and simulation to plan, analyze, and optimize virtual manufacturing systems and processes. An important part of the overall research idea was to use novel interactive visualization and analysis methods from computer science to create new answers to research questions in manufacturing engineering. The participation of scientists from physics contributed to advancing models and simulations by including physical properties of the factory objects.

In order to achieve the objectives of IRTG 2057 it was necessary to include physical properties in manufacturing models and simulations in a multi-level and multi-scale approach. Thus, research on techniques to simulate, visualize, and analyze manufacturing processes on different levels and scales formed the core of the research program. For this, physical models of manufacturing processes, machine tools, measurement devices, and entire factories as well as advanced simulation methods and new principles to visualize the results needed to be investigated. Furthermore, new methods and algorithms which allow real-time interactions with the physical models were to be found.

The research program of IRTG 2057 closely integrated the core competencies of the three partner universities RPTU Kaiserslautern-Landau, UC Berkeley, and UC Davis from the very beginning. At RPTU Kaiserslautern-Landau, all research areas of this IRTG were covered completely. The Principal Investigators (PI) at UC Berkeley and UC Davis each covered a significant, but not complete range of the topics, so that all topics were covered at the two combined partner universities as well. In the area of manufacturing systems and processes, both UC Davis and UC Berkeley provided an excellent and complete environment. Engineering mechanics research in IRTG 2057 was concentrated at UC Berkeley, data visualization and analysis were located at UC Davis.

Implementation of the central research idea

During the IRTG, a research program with more than 83 dissertation projects running at the three partner universities was established. These dissertation projects, ranging from molecular dynamics simulations of cutting processes to interactive visualization techniques for physical properties on the factory level, covered many important research questions in the physical modeling of an entire manufacturing system. Thus, the combined research in IRTG 2057 contributed significantly to the goal of making physical models available for the most relevant aspects of manufacturing systems and processes.

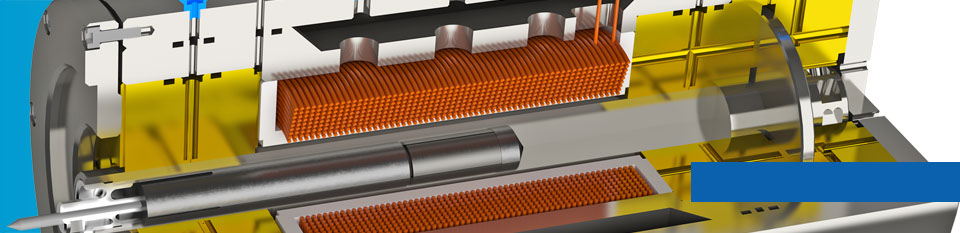

As laid out in the proposal to establish IRTG 2057 nine years ago, the research program followed a structure with three different levels of detail (factory, machine, and process) with complementing level-bridging projects. On the factory level, physical features and material properties were included in the material and information flow to describe the operating sequence of the manufacturing process chains accurately. On the machine level, machine tools and their components as well as measuring instruments were specified as virtual physical models. On the process level, various manufacturing technologies were investigated. Their detailed characteristics were described by physical models and simulations. To attain a comprehensive view of the manufacturing system, the correlations and interdependencies between the elements on each level as well as between different levels were part of the level-bridging research.

The close collaboration between projects from mechanical engineering, physics, and computer science was one of our prime objectives at the beginning of the IRTG. It was achieved in many of our projects, several examples are found in the detailed project descriptions in the annex of this report.

In summary, the central research idea of IRTG 2057 could be fully implemented and worked out exceptionally well. The importance of modeling and simulation for virtual manufacturing systems has further grown during the IRTG with cyber-physical production systems or Industry 4.0 now being one of the most important areas of research in manufacturing technology and beyond. IRTG 2057 was part of the world-wide research working on the founding basis of cyber-physical production systems and the integrated research of scientists from mechanical engineering, physics, and computer science became a model for research in the area of digitalization.

Scientific findings achieved

Many of the exciting scientific results which were achieved during the IRTG can be attributed to the close interdisciplinary and international collaboration between the members of this IRTG. Due to space limitations, we refer to the detailed reports of the doctoral and postdoctoral researchers in the annex of this document. Also, we refer to proceedings of our three international conferences that were organized by the IRTG [IRTG17; IRTG20; IRTG23].

In order to allow the simultaneous virtual validation and prototyping by multiple users, a framework supporting collaborative work in Virtual Reality (VR) has been realized. Using smartphones or tablets as secondary displays allowed to provide a private and detailed view of data. In order to enhance the interaction capabilities in more intuitive and natural ways, body movement gestures with the use of smartwatches were explored and integrated in a fully immersive VR environment. This created opportunities for the collaborative planning of manufacturing systems and processes at a whole new level. The dissertation projects from computer science dealing with interactive visualization thus collaborated closely with the projects from manufacturing engineering and factory planning. The excellent quality of the results in both disciplines would not have been possible without this collaboration.

A framework supporting collaborative work has been realized that scales in terms of degrees of virtuality (i.e., from reality to Mixed Reality (MR) to Virtual Reality (VR)), in terms of devices (i.e., handheld and head-mounted displays) and in terms of the number of users (i.e., from single users to multiple possibly distributed users). Thereby, full scalability regarding options of interaction can be provided through the integration of a robotic system that allows off-site users to manipulate real scene components on site. In this context, the application of MR handheld displays for robot control has been investigated in close cooperation between RPTU Kaiserslautern and UC Davis.

The development of a virtual measuring instrument enabled a deep understanding of the interaction between a specific measuring principle and the physical quantity. Based on ray tracing algorithms, a virtual coherent scanning interferometer and an angle resolved scattering light sensor were implemented in a C++ environment. To ensure fast processing, the software architecture uses the graphics processing unit in multithreading mode. E.g., a virtual measuring instrument was embedded in a virtual manufacturing system in order to find the best measurement setup for a given measurement task.

Molecular dynamics methods, which have been established in natural sciences for quite some time, are still relatively new in manufacturing research. Here, IRTG 2057 was able to take a leading role on the basis of the close collaboration between natural sciences and manufacturing research. Results with direct applicability in manufacturing were achieved and experimentally validated. This collaboration greatly helped to establish a new W2/W3 tenure track professorship “Computational Physics in Engineering” at RPTU Kaiserslautern.

The Particle Finite Element Method was successfully applied to cutting processes. It turned out that an important algorithm, the so-called alpha shape method, strongly influences the simulation outcome. This method that originates from computer graphics determines the boundary of a point set. If applied to solid materials, the method is capable to describe material separation. During the first funding period, it was discovered in close cooperation between RPTU Kaiserslautern and UC Berkeley, that a continuum mechanical interpretation of the alpha parameter can be given in terms of critical strains. Thus, the predictive capability of the particle finite element method could be improved, as a better physical understanding of the alpha parameter is now possible. With regard to phase field methods, the extension to dynamic settings was crucial to cope with the high loading rates and elastic waves that occur during many manufacturing processes. In addition, the coupling to other field problems, especially the thermal problem, extended the field of application to laser-based manufacturing process.

In the second funding period, the Particle Finite Element Method (PFEM) was developed further to simulate additive manufacturing processes. The ability of the method to handle complex geometrical and topological changes allowed for an easy adaptation to additive manufacturing. The addition of material is treated by creation of new „particles“ in the point cloud that defines the computational domain in the PFEM. The concurrent FE simulation can consider temperature and mechanical deformations as well as other physical processes.

The fracture phase field model was successfully extended to fatigue fracture processes. The existing model was modified such that fatigue material data from S-N-curves can directly be incorporated in the simulations. The development of fatigue fracture phase field models is an active field of scientific research. The model developed in the IRTG is based on a damage mechanics approach in conjunction with the phase field approach and shows good predictive properties in applications ranging from manufacturing to materials science and engineering.

The level-bridging projects were – as expected – particularly challenging. The post-doctoral researchers focused in the level-bridging projects and the physical modeling of sustainability indicators of a manufacturing systems was achieved in a collaboration between UC Berkeley, UC Davis, and RPTU Kaiserslautern.

Thematic networking between the partner universities and scientific added value

The cooperation between RPTU Kaiserslautern-Landau and the partner universities UC Berkeley and UC Davis allowed progress in several projects of this IRTG which would not have been achievable at one single location.

RPTU Kaiserslautern could for instance profit from computer science / programming know-how at UC Davis and introduced new tools to its manufacturing simulations (i.e. the use of Python and JSON in simulations on the factory level). Expertise in additive manufacturing was built at UC Berkeley and UC Davis during the first funding period and largely influenced the projects of the second funding period at RPTU Kaiserslautern. The doctoral researchers from UC Davis and UC Berkeley used the advanced measurement and manufacturing labs at RPTU Kaiserslautern for experimental investigations and validation of the results of simulations which would not have been possible at UC. While many instances can be found in the reports of the doctoral researchers in the appendix, some exemplary collaborations are presented in the following paragraph.

A close collaboration of the computational materials science group at RPTU Kaiserslautern (Prof. Urbassek) and the Laboratory for Manufacturing and Sustainable Technologies Research at UC Davis (Prof. Linke) was established during the first funding period. As a result, methods of molecular dynamics were applied to the question of evolving residual stresses during machining. This collaboration was strengthened in the second funding period by including the modeling of poly crystalline materials to achieve even more realistic results. Another example is the collaboration between the groups of Prof. Aurich and Prof. Linke. Through the IRTG, a strong collaboration was fostered that allowed to successfully apply for a joint project funded by NSF and DFG to understand the prime factors driving distortion in milled aluminum workpieces. The second PI of this project at UC Davis was Prof. Michael Hill, who then joined the IRTG in the second funding period as PI.

Overall, there were 130 exchange visits by doctoral researchers and 99 visits by PIs between the partner universities (approximately two thirds of those from Germany to California and one third from California to Germany). These numbers document the success and the acceptance among the participants of the international aspects of our IRTG.

During all exchange visits, no fees were asked for and the doctoral researchers were able to participate in all classes and courses. Furthermore, they were fully integrated in all activities of the hosting group and worked in close contact with the respective PI’s.